Once the layout is finalized, there are several optimization tools that the operator can use to reduce cutting and punching times. Depending on how many parts are needed and the size of the sheet, specified values for clamp areas, parts spacing and parts placement can be changed to reduce waste to a minimum. The software will display the resulting layout and the operator can then still make changes to use the sheet optimally. Before the software places the parts on the sheet, the operator has to define part spacing and room for clamps. Specifying the metal sheet size helps determine the parts layout. In each case, the operator can review the list of tools and replace or change any if needed. Operators can often choose available tools to carry out cuts and punches for which different tools were originally specified. Replacement tools may be selected from a list within the program or another available machine can be chosen. Sometimes a part may require a tool that is not available on the machine the operator chooses. When they choose a CNC machine, the software may assign punches (or lasers) or they can make the assignments manually.

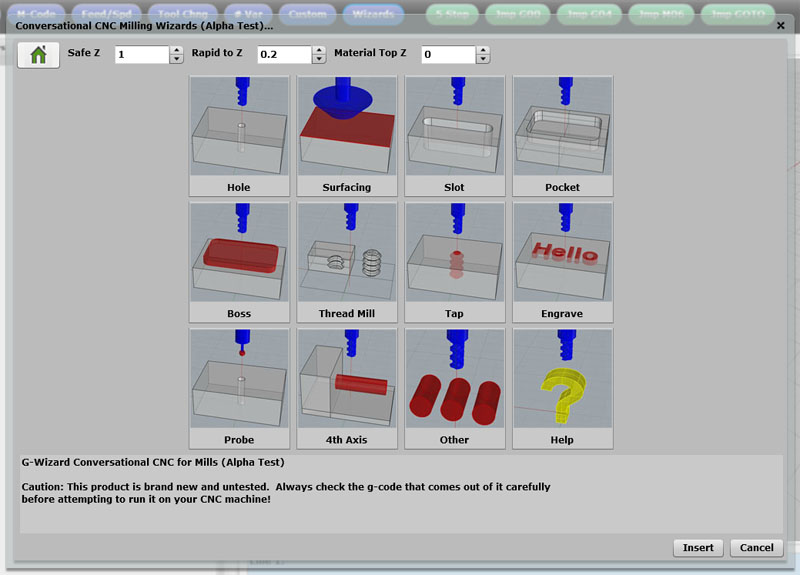

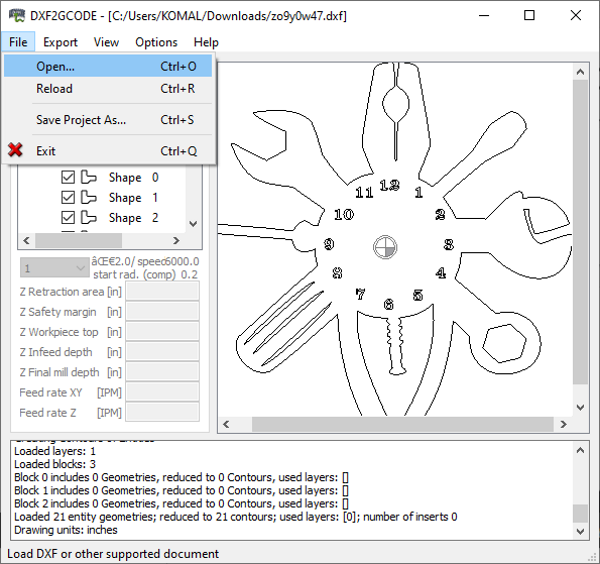

They may be able to select the material from a material library or they can specify the type of material and its thickness. In other words, dxf to gcode.īefore the sheet metal software can write gcode, operators have to specify what machine will be used and what material will be cut and punched. The result is optimized code that is customized to deliver top quality output. Some routine functions may be automated, but there can also be an interactive mode in which the operator can make specific changes to meet the requirements of a particular job. Sheet metal software can help operators create code that maximizes throughput. Steps that result in efficient layouts and short tool paths are time-consuming to carry out manually and the results are often not optimized fully. dxf files are available, the parts drawings can be processed but before the G-Code specifying tool paths can be written, there are several additional steps that have to be carried out.

Today's CAD/CAM solutions can read a wide variety of file types including DXF files. dxf (Drawing Exchange Format) CAD file type is a common type of input file for the fabrication of sheet metal parts and other file types are often converted to dxf before further processing. The in-house CAD/ CAM software of the sheet metal fabricator has to be able to import or read these files and convert them to file types the in-house software can use. Sheet metal fabrication shops have to work with many different file types as their customers place parts orders using output files from their own CAD programs.

0 kommentar(er)

0 kommentar(er)